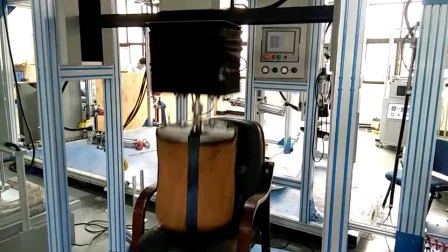

Electronic Office and Furniture Chair Strength Durability Testing Machine

Electronic Office And Furniture Chair Strength Durability Testing Machine DESCRIPTIONThe machine is designed to test off

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | HD-F743 |

| Display | Digital, LCD |

| Control | PLC Control |

| Weight | 100-500Kg |

| Power Source | AC220V |

| Emergency Button | Arm Vertical Test Grips |

| Test Accessories | One Test Platform for Arm Test |

| Power | One Phase, AC 220V, 50 Hz. |

| Number and Cycles | One Back Strength Test Grips |

| Setting Time | 0-99s ( Adjustable) |

| PLC Control | LCD Touch Screen Interface |

| Capacity | 0-200kg |

| Product Name | Chair Strength Tester |

| Transport Package | Strong Wooden Case |

| Specification | Size: 1500X1400X1800mm |

| Trademark | HAIDA |

| Origin | Dongguan, China |

| Production Capacity | 150 Sets/Month |

Product Description

Electronic Office And Furniture Chair Strength Durability Testing MachineDESCRIPTIONThe machine is designed to test office chair arm ( vertical and horizonal test ) and back strength. It with PLC controller, touch screen interface to input test parameters, test force and times can be set.

GENERAL SPECIFICATIONS

Machine Dimensions: (W x D x H) 2450mmx1000mmx2250mmCompressed air requirement: 6-7kg/ cm2Electrical Consumption: 0.2KWPower supply source: single-phase, AC220V±10%, 50/60Hz (can be appointed)Gross Weight: 380kg

APPLICATION STANDARDS: BIFMA X5.1-2017 section 5, 6, 12, 13, 14, 15

STANDARD FEATURES

| Items | Description |

| Capacity | 2kN Imported sensor (Durability test)5kN Imported sensor (Strength test) |

| Load weight | 109 kg (one set) |

| Test speed | Durability test 5 ~ 20 times /min,Strength test 450mm/min |

| Test force value | Durability test 450N ~ 1.5kN (cylinder driven)Strength test MAX 1.9kN (motor driven) |

| Display mode | Touch screen interface |

| Control mode | PLC control |

| Setting time | 1 ~ 999,999 times (adjustable) |

| Overall dimensions | 2450mmx1000mmx2250mm (L*W*H) |

| Weight | About 250 kg |

| Air | Acuity 0.6 MPa |

| Power | 1∮, AC 220V, 50 Hz. About 200W |

| Main test items | Chair back fatigue test and damage test,Chair armrest horizontal and vertical fatigue test and damage test |

CONFIGURATION:

| Configuration | Name | Details |

Items | Documents | Operation Manual*1 piece;Factory Inspection Report*1 piece;Operation Video in USB flash disk with machine*1 piece |

| Power line | 1 piece | |

| Plug | 1 piece(Per your local plug standard) | |

| USB flash disk | 1G capacity *1 piece | |

| Force sensor | 2KN Capacity *1 piece5KN Capacity *1 piece | |

| Weights | 109kg*1 set | |

| Air pipe | 1Φ 8 tracheal * 1 piece | |

Clamps | Chair seat fixing fixture *1 pieceHandrail vertical clamp *1 piecePull back fixture *1 pieceChair foot pressing block *1 pieceRibbon pressing block *1 piece |

REFERENCE DOC: BIFMA X5.1-2017Section 5 Backrest Strength Test - Static- Type I Test Procedure:A force of 667N (150lbf) or 1001 N (225 lbf) shall be applied to the backrest at the backstop position for 0ne minute. Angle 70 ± 10 degrees, If the backrest/tilt lock mechanism will not accept the load due to gradual silpping of the adjustment mechanism during the load application, set the backrest to its most rearward(stopped) position, then apply the specified load(s). Remove the loadSection 6 Backrest Strength Test - Static- Type II & III Test Procedure:Same with section 5, only the force should be 667N (150lbf) or 1001 N (225 lbf), Angle 90 ± 10 degrees.Section 12 Arm strength Test- Vertical- Static Test Procedure: A force of 750 N (169 lbf) or 1125 N (253 lbf) shall be applied for one minute. Remove the forceSection 13 Arm strength Test- Horizontal- Static Test Procedure:A force of 445 N (100 lbf) or 667 N (150 lbf) shall be applied for 15 second in the outward direction.Remove the force.Section 14 Backrest Durability Test - Cyclic - Type l Test Procedure:For chairs with backrest widths less than or equal to 406 mm (16 in.) at the height of the loading point, apply the load to the backrest for 120,000 cycles.For chairs with backrest widths greater than 406 mm (16 in.) at the height of the loading point, apply the load to the backrest for 80,000 cycles.Section 15 Backrest Durability Test - Cyclic - Type Il and lll Test Procedure:For chairs with backrest widths less than or equal to 406 mm (16 in.) at the height of the loading point, apply the load to the backrest for 120,000 cycles.For chairs with backrest widths greater than 406 mm (16 in.) at the height of the loading point, apply the load to the backrest for 80,000 cycles.

The Introduction Of HaidaHaida products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and are applicable to all scientific research units, quality inspection institutions and academic fields. Our products meet UL, ASTM, JIS, GB,SO, TAPPI, EN, DIN, BS and other domestic and international standards.If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.1. Pre-service24 Hours online service for your consult.Help choose right model,and a series of service,person,advise. main web site:http://haidaequipment.en.made-in-china.com2. Middle service--Give you best offer--Provide discount for many sets order--Do customer's request:--Choose payment term you convienent.--Promptly production and delivery,inform you in time.--Can provide invoice value as you like to decrease your tax.3. After sale service--1 year warranty service and all life maintenance.--Technical Egineer are avalible for oversea trainning.--Free change for some parts--Remote control technical consult--Free installation DVD--Maintenance plan4,Commitment:We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.5,Good Packaging:Good Packaging: Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.client feedback